Brengor Innovation

New safety razor design could save lives and help the environment

A team from the University of Strathclyde's Advanced Forming Research Centre (AFRC) collaborated with Darren Haley, former prison officer and owner of Brengor Innovation, who has developed a recyclable razor designed to reduce incidents of self-harm.

Brengor identified that many of the 60,000 self-harming incidents that occur each year in secure environments across the UK could potentially be prevented if staff and service users had access to a razor designed with harm and violence reduction integrated into its design.

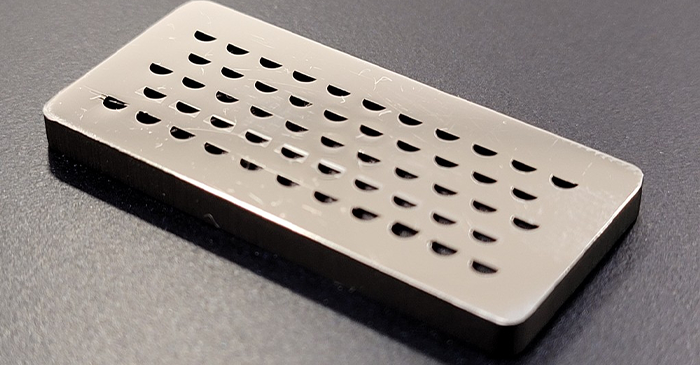

Its patented harm reduction razor head design comprises a solid piece of stainless steel and 66 sub-micron cutting edges and is safer than a traditional razor because it can't be bent or manipulated to expose dangerous sharp edges. The design has also been created with sustainability in mind by incorporating recyclable materials and a blade re-sharpening service.

Customer challenge

Looking to manufacture the product at a low cost while producing over 1,000 units a day, the Leeds-based organisation wanted to investigate the best manufacturing process to help scale production.

Brengor had previously explored manufacturing methods such as CNC machinery and metal injection moulding, but found they were too costly and didn't meet performance requirements. It approached the AFRC to investigate the hot forging process to meet the product's cost, geometrical, performance, and mechanical requirements.

How did the AFRC help?

The AFRC's Forming team looked to determine the best manufacturing method for accurate, repetitive outputs and take Brengor's razor design concept to a stage where it could be rolled out to test sites.

Sets of finite element (FE) simulations were created that tested the design at different temperatures and strain rates to evaluate the manufacturability of the product and determine the required technical parameters for the forging press.

The feasibility of forging the part with the dimensions and features in the design was considered against the modelling outcomes, literature review, component manufacturing, and die set manufacturing.

Darren Haley, Owner, Brengor Innovation said:

As a former senior prison officer, I have seen first hand the injuries and damage a prison razor can inflict. The harm reduction razor has the potential to significantly reduce violence, self-harm and suicides in secure environments such as prisons and mental health hospitals. The primary challenge is using methods suitable for mass manufacturing and reducing materials waste.

"The AFRC has worked very hard to produce evidence that demonstrates the viability of hot forging as a method of mass production. I look forward to working with them on the next stages of the pathway to market.

Business impact

Brengor has selected the best manufacturing route for its product and secured several UK test sites, such as prisons and mental health hospitals, where the company can observe the potential impact on safety.

It has also identified that the razor is suitable for the general market, offering significant benefits compared to traditional razors, including being 100 % recyclable and less likely to produce unsightly skin cuts.

By offering a blade re-sharpening service, Brengor can significantly increase the product's life cycle. All discarded blades currently end up in landfills, and there is enormous potential to reduce both waste and emissions within the sector.